- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Maximum output for a minimal investment in the smallest footprint

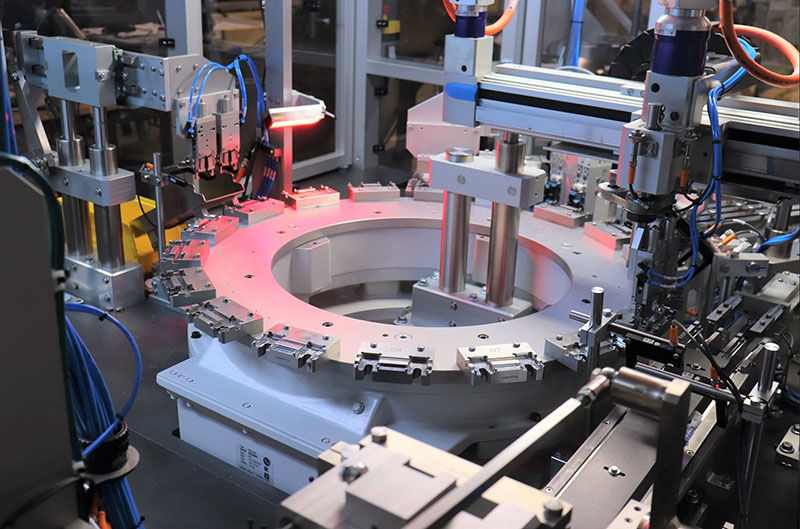

SYMPHONI™

An innovative high-speed manufacturing solution that combines standardization and speed with gentle part handling. Assembly rates from 40 – 1100 PPM with a much smaller footprint than conventional assembly equipment.

Symphoni™

Digital assembly platform that is pre-engineered, highly standardized and modular. A general-purpose asset that surpasses conventional systems in flexibility, speed, and precision.

- Patented RSM Technology® enables tight coordination of integrated, multi-axis robotic arms

- Compact, configurable, and modular construction reduces footprint

- End-to-end digital awareness, with status and position of each system device, mapped out in 1-millisecond intervals, verified 200 times per second by self-diagnostics

Features

- High flexibility of pallets & robots

- Pre-engineered, plug-and-play design

- 85% standardized and modular; 90% less tooling than conventional equipment

- Ultra-precise motion control with a delicate touch

Applications

- R&D

- Clinical and low-volume production

- High-volume assembly; variable speed capable of 10 – ~1000 ppm

- High-volume/low-mix & low-volume/high-mix products

Recommended For

- Autoinjectors, pens (4 – 10 components)

Output: up to 400 ppm - Eye dropper bottles and lids (2 – 3 components)

- Inhalers

Output: up to 320 ppm

Key Benefits

Symphoni goes fast where it can and slow where it must. Critical process times are never compromised.

Configurable

Configurable

Modules can house up to two stations that may include pick-and-place, Vision for part orientation/pre-inspection, 3rd-party units such as welders and filling heads

High-Efficiency Synchronous Operation

High-Efficiency Synchronous Operation

Multi-axis movement in which the position, velocity, and acceleration of each device are mapped in 1-millisecond intervals

Performance

Performance

More output per CAPEX dollar, more output per square meter of floor space. Multi-axis configurability and synchronized motion optimize ROI for 20 PPM or 1000

Infinitely Flexible and Versatile

Infinitely Flexible and Versatile

Run the machine clockwise or counterclockwise for similar size products with a different process; change touch tooling (end effectors) to assemble different products on the same shift; change the tool deck for different products and processes.

Other Assembly Solutions

Autoinjector Platform

Pre-assembly to final assembly, semi-automated to fully automated systems tailored to specific requirements

Syringe Platform

Linear motion platforms that enable synchronous and asynchronous processing and configurable transfer systems for aseptic environments

ATS Jetwing

Introducing and removing components, subassemblies, and finished product is a key aspect of an efficient operation

ATS OmniTrak

Product quality control and assurance through smart test, inspection, and digital monitoring

ATS Discovery

Product quality control and assurance through smart test, inspection, and digital monitoring

Symphoni™ Gives You the Edge

Technology that transforms the way you invest in automated assembly. Enhanced servo-based motions and e-cams mean a single system can run multiple product lines 24/7with 90% less retooling.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube