- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

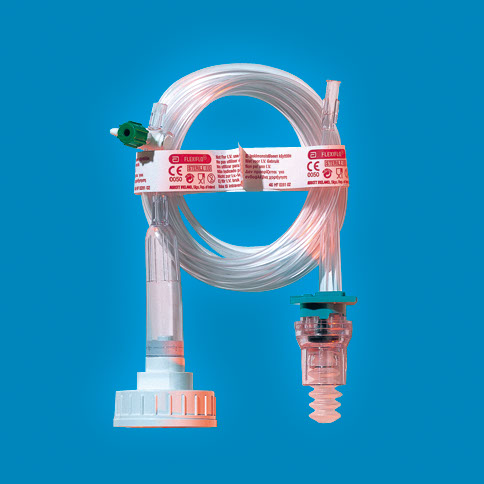

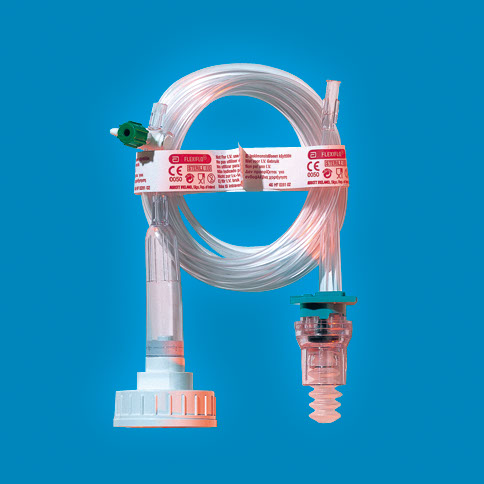

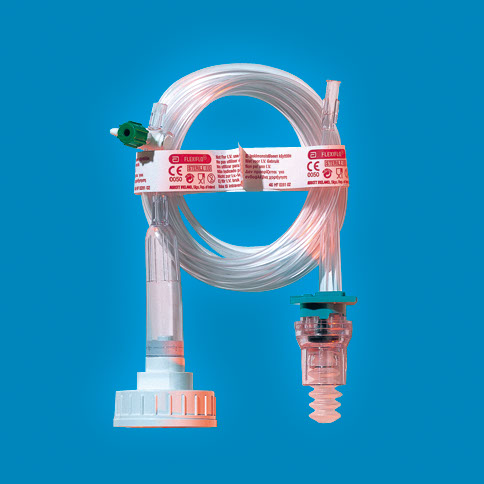

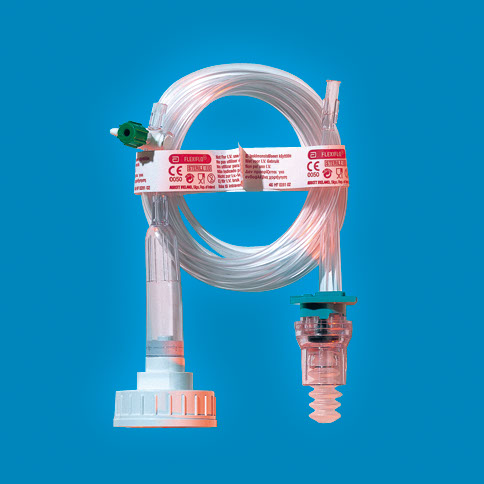

Medical Tube Sets

Output Level: Up to 60 ppm

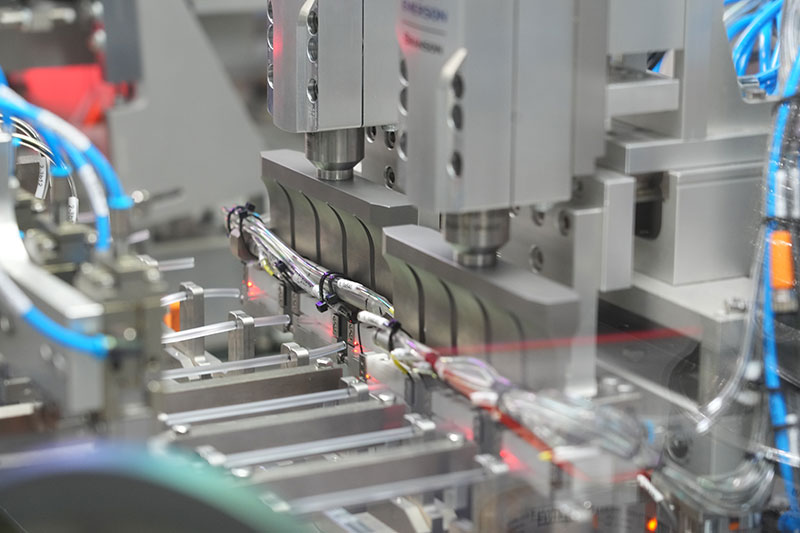

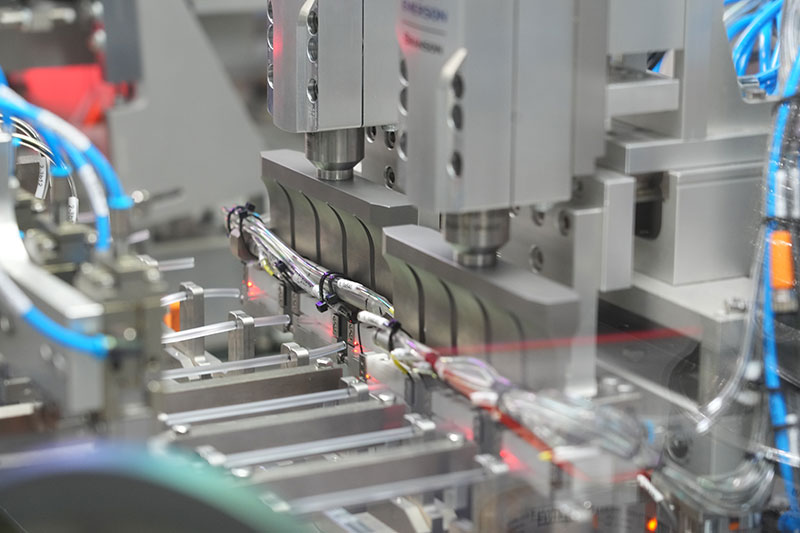

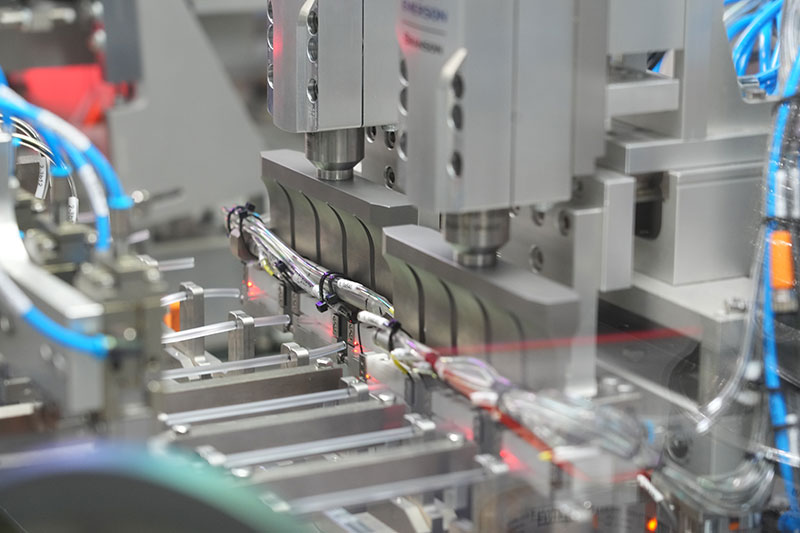

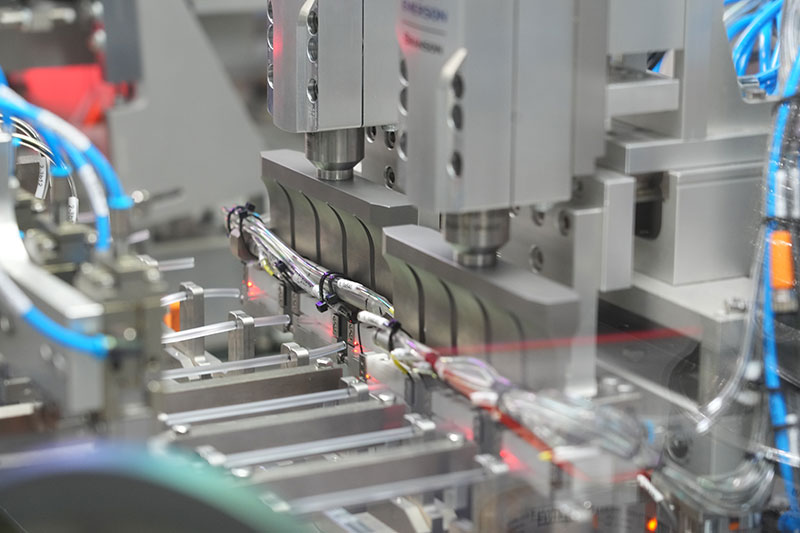

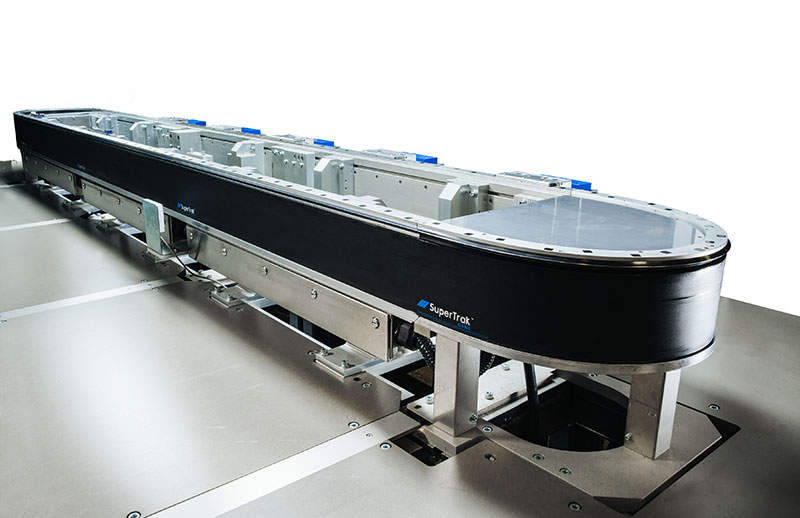

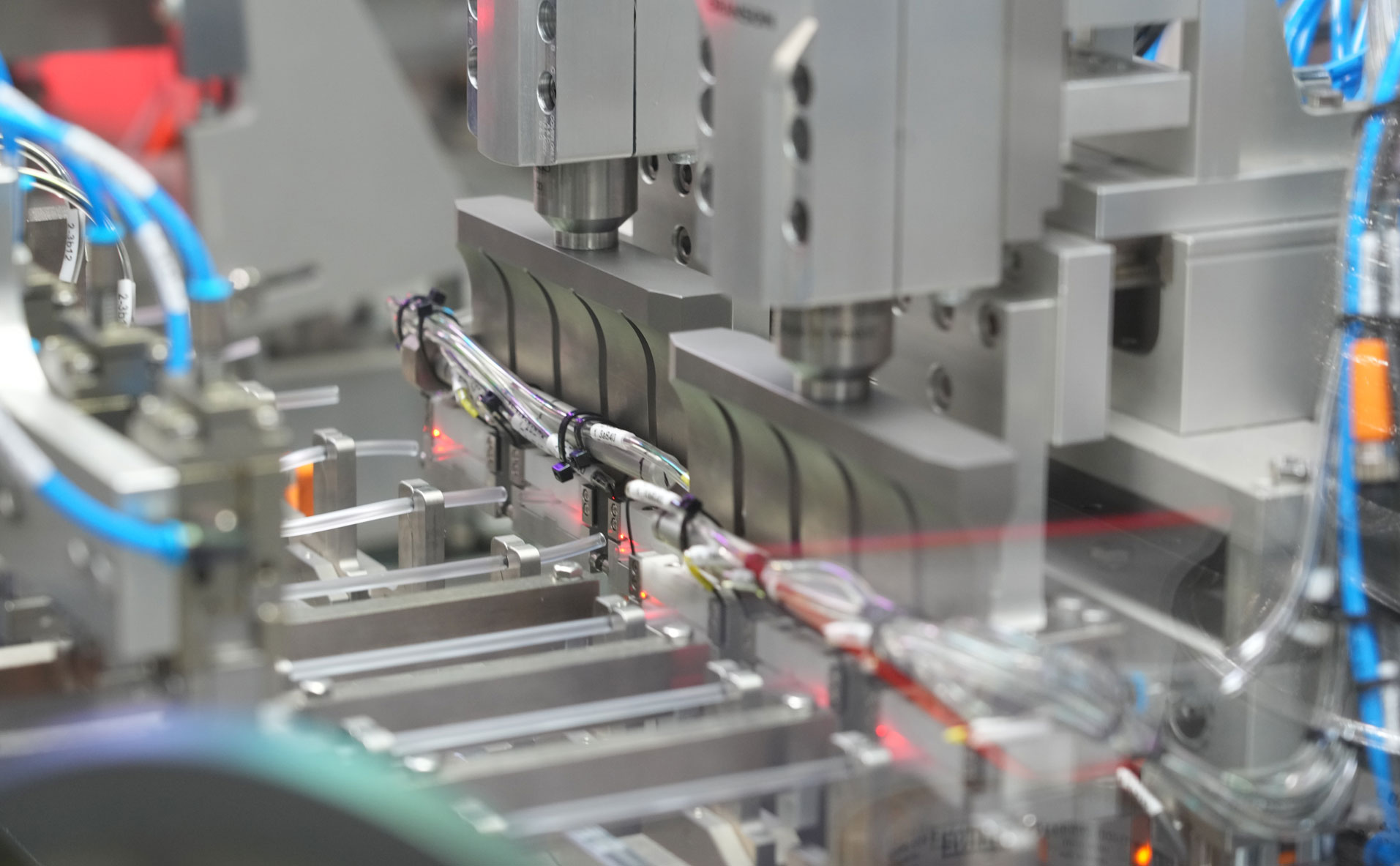

The MDCoiledTubeSet60 is a synchronous, servo-driven machine on a SuperTrak CONVEYANCETM smart conveyance platform. Dual sided de-reelers allow for tube changeout without stoppage. Vibratory hoppers meter parts for hours of walkaway time.

- Product – Complex coiled

- Platform – SuperTRAK CONVEYANCETM

- Cutting – Ultrasonic blade

- ISO Level – ISO 8 standard, or custom

Medical Tube Sets

Output Level: Up to 60 ppm

✕

COILED SETS

Features

- Output up to 60 ppm

- Faster rate: Smaller footprint and fewer material loading points (less operator time)

- Ultrasonic cutting – Blade vibrates at a high frequency (20,000-80,000 Hz) for a cleaner cut, reduced risk of particulate and micro plastics, and increased sustainability

- Equipped with IlluminateTM Manufacturing Intelligence to rapidly debug and statistically track throughput

Recommended for

- Complex coiled tube sets

- Simple coiled sets

- Non-stop operation – Dual-sided de-reelers allow for changeout of tube without machine stoppage

- ISO 8 cleanroom: Standard is ISO 8 but can be designed to go lower

Learn More About Smart Conveyance

SuperTrak CONVEYANCETM is a fully programmable linear motion technology with independent and parallel workstations. Smart technology with asynchronous sub 10 micron resolution and precision, single PLC control system, fully scalable and configurable to meet complex challenges and varying outputs.

Learn More About IlluminateTM Manufacturing Intelligence

Utilize onboard reporting and diagnostic tools for production performance monitoring. Simplify the collection and analysis of data from automated manufacturing systems. With Illuminate software installed, operations and maintenance personnel can quickly understand situations and prioritize actions.

Resources

Infographic

8 Ways to Maximize the Performance of Your Tube Set Assembly System

From design for maintenance and reliability to purchasing certified parts.

Blog

Exploring the Innovations Behind our Tube Set Assembly: Features That Make a Difference

When manufacturing medical tube sets, two of the most important factors to the manufacturer include output volume and product quality.

FAQs

Transforming Tube Set Manufacturing with Automation

Most commonly asked questions about the ATS solution, quality control, expansion and delivery.

Podcast

E2: Breaking Down the Cost / Quality Paradigm in Tube Set Manufacturing

Hidden costs, and flexibility in design/multiple recipes to address them. Variances in material, and choosing the right machine for the job.

Built on Proven Hardware, Time to FAT is Compressed by Leveraging Standard Designs.

A synchronous, servo-driven tube set machine stationed on a SuperTrak CONVEYANCETM smart conveyance platform for medium to high output.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube