Ultra-low Dispensing for Miniaturized Diagnostics

Scaling Up Complexity for Diagnostics and Wearables in a Quick-to-Market Solution

A single modular, automated platform for miniaturized diagnostics manufacturing with integrated ultra-low dispensing technology and smart conveyance platform accelerates time to market and provides full scalability for a customer needing to scale up production.

THE PROBLEM

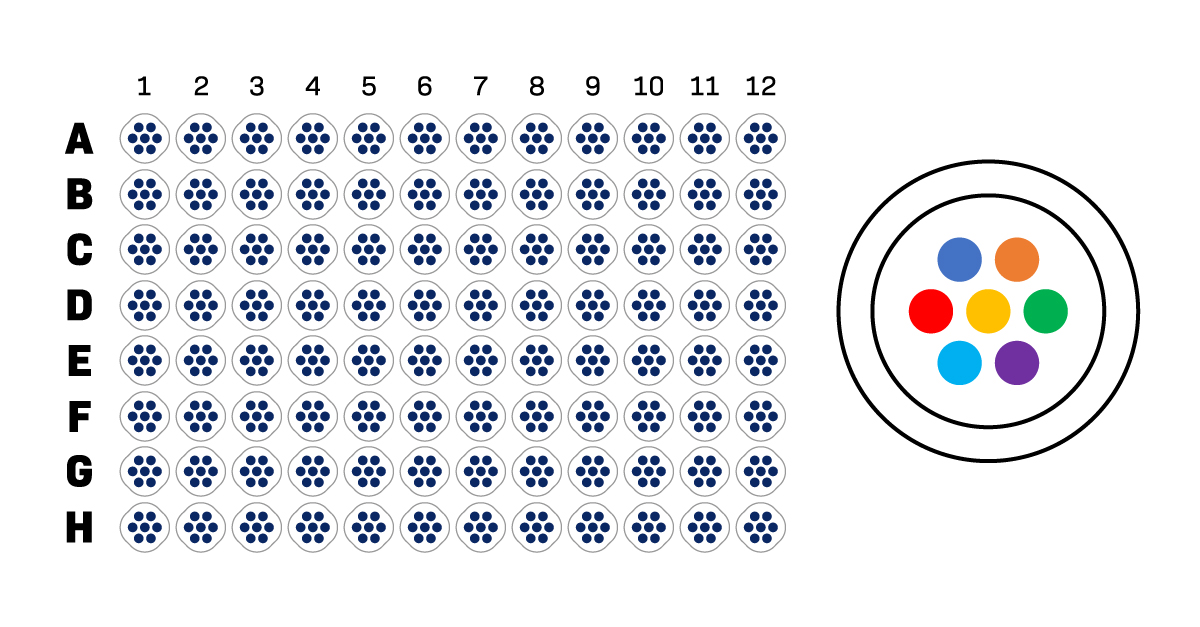

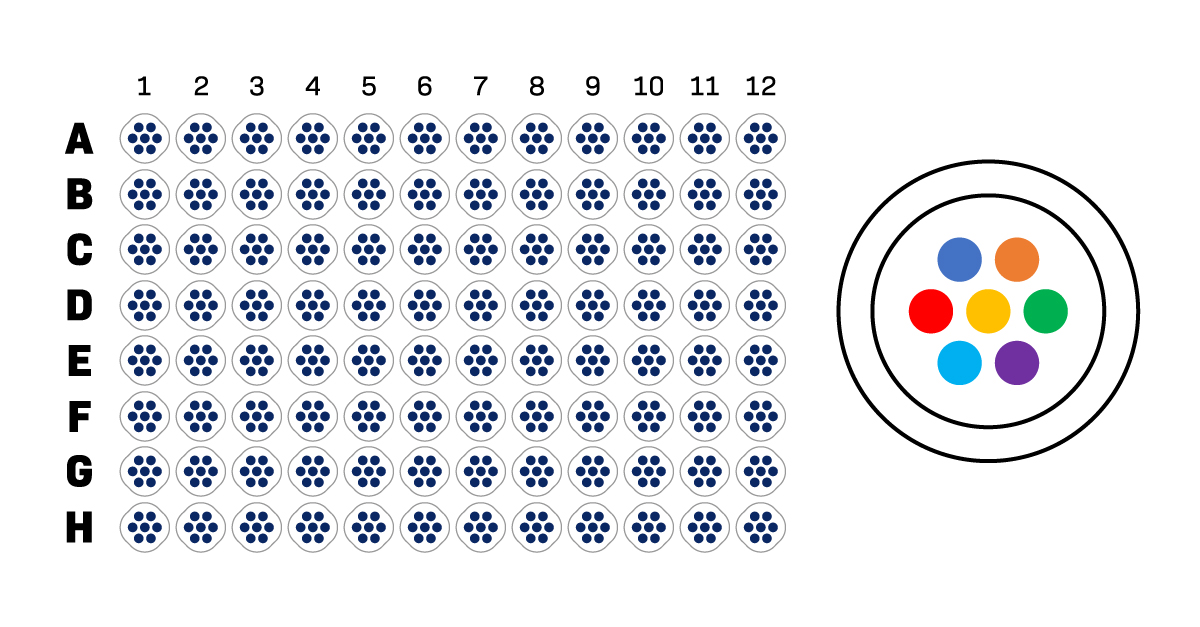

The customer wanted to develop and build a customizable multiplex ELISA 96-well plate production line with the capability to deliver a multiplex array with seven biomarker chemistries at an initial target production rate of 2.5 parts per minute (ppm).

Key criteria for acceptable design included capital cost, short time to deliver the manufacturing process, capability to scale up as demand increased, and maximum automation with reduced operator input.

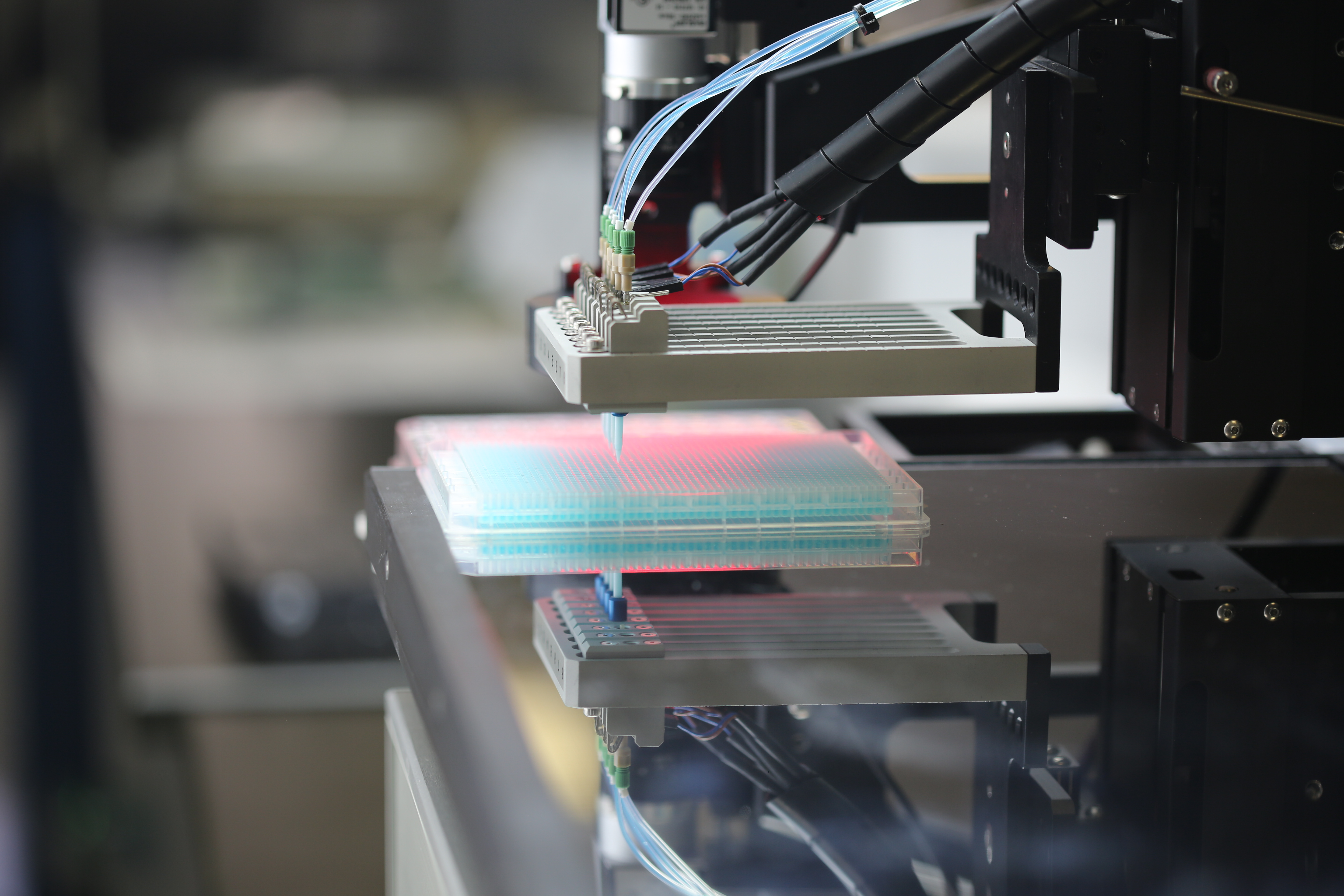

The AD6020 combines BioDot’s precision low-volume dispensing technologies and a large customizable nest to create a high throughput, multi-channel automated liquid handling workstation. Nests for MTPs and slides are available, or the system can be customized for unique spotting surfaces and/or labware. Manufacturing throughput can be optimized through single/dual shuttle nest designs.

As a standalone solution, the AD6020 can produce the multiplex array with seven biomarker chemistries, but the production rate is limited to 0.36 ppm. The traditional approach would mean that seven separate AD6020 systems would need to be installed in parallel to achieve the customer’s target product rate. Other downside issues were:

- the resulting significant footprint space,

- he need for a dedicated operator for each machine, increasing headcount and ongoing resource costs, and

- no capability to scale up as production demand increased.

THE SOLUTION

Creating Scalability: ATS Life Sciences Systems and Biodot, partners in the ATS LS Group, collaborated and developed a new, scalable, customizable, and rapid-to-market solution for miniaturized diagnostics manufacturing, which overcomes the limitations of traditional design approaches.

The MODULISTM solution combines the ultra-low dispensing expertise of Biodot with SuperTrak CONVEYANCETM technology and ATS LSS’ integration and project delivery excellence to deliver a tailored, flexible, scalable, and seamless miniaturized diagnostics manufacturing solution with a reduced lead-time and lower capital and operational investment.

A single MODULIS line can be designed with multiple automated liquid handling workstations which work in tandem with the rapid, configurable conveyance line to significantly increase the parts per minute throughput and comfortably meet the 2.5 ppm target while being scalable for future demand increases.

Reducing Time-to-Market: Customer requirements are almost always unique, which puts pressure on the ability of the supplier to take a product from concept to final manufacturing line in the shortest timescale to optimize the time-to-market. ATS has addressed this with the MODULIS solution as a significant part of the front-end design has been standardized, which significantly reduces the Design, Procurement, Assemble, and Test period and accelerates the workflow to FAT and full production.

Reducing Total Cost of Operation: Comparing MODULIS directly against seven AD6020 systems installed and operated in parallel to deliver the targeted 2.5 ppm capacity for multiplex array with seven biomarker chemistries would deliver an approximate 15-20% capital investment reduction and only one operator headcount compared to seven.

THE RESULTS

MODULIS not only provides the most scalable and quickest-to-market solution for miniaturized diagnostics manufacturing but also provides customers with the potential for both reduced capital investment and operator resources for system operation.

A modular, automated platform for miniaturized diagnostics manufacturing

Integrated ultra-low dispensing technology and smart conveyance provides the most scalable and quickest-to-market solution with the potential for both reduced capital investment and operator resources.

More Case Studies

BROCHURE

Your Pharma Projects, Our Proven Automation Solutions

Are you a pharma manufacturer? Learn about how we can help you with your project

BROCHURE

Your Medtech Projects, Our Proven Automation Solutions

Are you a medical device or diagnostic manufacturer?Learn about how we can help you with your project

Fact Sheet

Standard Autoinjector Manufacturing System

Pre-engineered for lower design costs and faster delivery; suitable for any common three-piece autoinjector

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube