- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Resources

Blog

6 Aug 2024

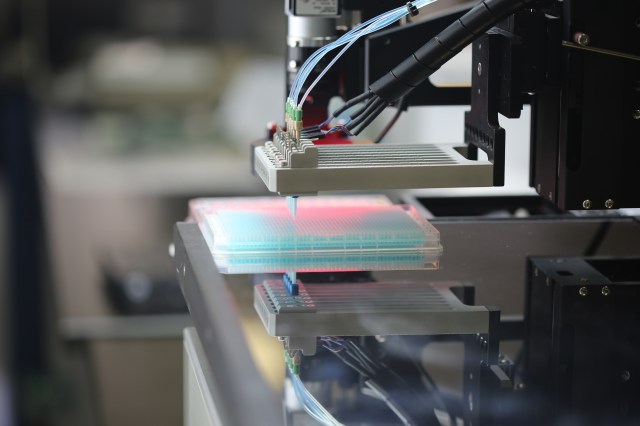

Choosing the Right Partner to Transform from Parts/Day to Parts/Minute Output – Centered on Ultra-Low Volume Dispensing in POC Diagnostic ManufacturingIntroduction Ultra-low volume dispensing for this discussion is the ability to dispense precise single droplets that are basically invisible to the human eye and defined in units of pico or nano liter volume. We care

11 Jul 2024

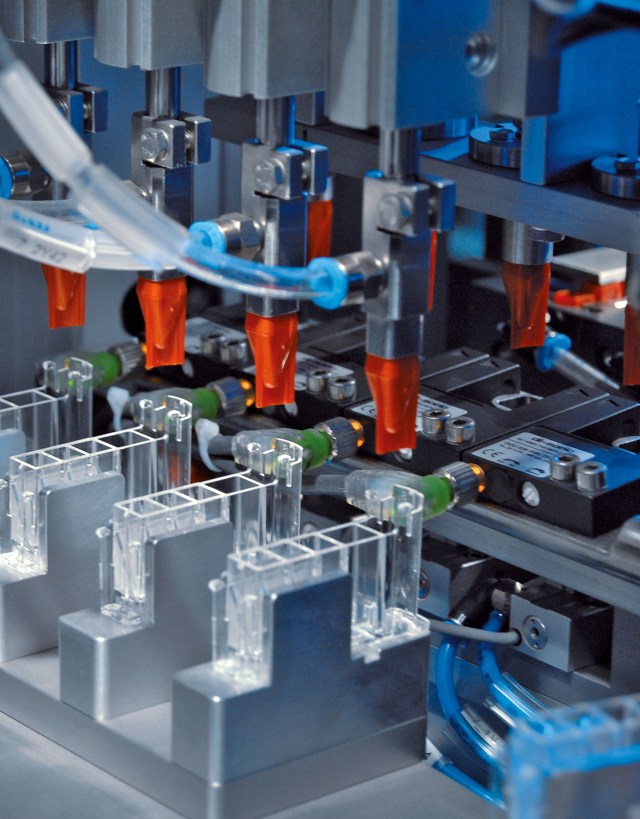

Introduction Why are Innovations in Tube Set Manufacturing Important? Complicating the expected growth in demand in tube set markets, many suppliers are also experiencing a labor shortage due to the high operator counts (typically 150-200+ workers per shift to output at needed rates) and intense dexterity demands required of manual tube set assembly. In Mexico,

Case Studies

An autoinjector is a complex mechanism that demands 100% quality to ensure each device functions correctly every time. At ATS, we were hearing from customers that they needed this quality but at faster rates. Given the ever-increasing demand for autoinjector assembly across all sectors, the engineers in the Innovation Center saw an opportunity to review our proven processes and technology, and challenge established monitoring rates. Initially the request was for two separate machines: one that could produce a syringe line and a second that would handle vials. After consultation with the experts in the ATS LS Group, we were able to present a hybrid concept, merging the two processes and delivering a single end-to-end solution capable of changing formats from one to the other, quickly and efficiently. Despite greater complexity, the revamped proposal was less costly and mitigated risk to both the product and to operators.

Our customer, a global pharma company, is a producer of a cancer drug containing both a liquid and a powder that is delivered via syringe. Their existing assembly process was outdated, required staff in full PPE garb in cleanrooms, and was not Class A. They wanted an automated aseptic filling, handling and packaging line that included containment of APIs in the form of a liquid and a cytotoxic powder, and that was capable of increasing production capacity. Initially the request was for two separate machines: one that could produce a syringe line and a second that would handle vials. After consultation with the experts in the ATS LS Group, we were able to present a hybrid concept, merging the two processes and delivering a single end-to-end solution capable of changing formats from one to the other, quickly and efficiently. Despite greater complexity, the revamped proposal was less costly and mitigated risk to both the product and to operators.

Our customer, a global pharma company, is a producer of a cancer drug containing both a liquid and a powder that is delivered via syringe. Their existing assembly process was outdated, required staff in full PPE garb in cleanrooms, and was not Class A. They wanted an automated aseptic filling, handling and packaging line that included containment of APIs in the form of a liquid and a cytotoxic powder, and that was capable of increasing production capacity. Initially the request was for two separate machines: one that could produce a syringe line and a second that would handle vials. After consultation with the experts in the ATS LS Group, we were able to present a hybrid concept, merging the two processes and delivering a single end-to-end solution capable of changing formats from one to the other, quickly and efficiently. Despite greater complexity, the revamped proposal was less costly and mitigated risk to both the product and to operators.

Video Hub

Events

24-27

Jun, 2025

Automatica

As the leading exhibition for smart automation and robotics, Automatica features the world’s largest range of industrial and service robotics, assembly solutions, machine vision systems, and components. It gives companies from all relevant branches of industry access to innovations, knowledge, and trends with a great deal of business relevance.

04-06

Feb, 2025

ATX West

As the largest annual automation technology event in North America, ATX West hosts top manufacturing companies in automation, robotics, and motion control assembly, as well as SMEs that are actively sourcing products and solutions. More than 1,400 exhibitors and 13,000 visitors attend the event.

News

17 Jun 2024

ATS Life Sciences Systems (LSS), headquartered in Cambridge, Ontario, Canada, is pleased to welcome the team at the Process Automation Solutions location in Prague, Czechia, into the LSS fold.

13 Jun 2024

Staubli Robotics Continues to Support ATS Life Sciences Systems with Upcoming Robotic Syringe Assembly.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube