- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Discover the possible applications for industrial robots

ROBOTS

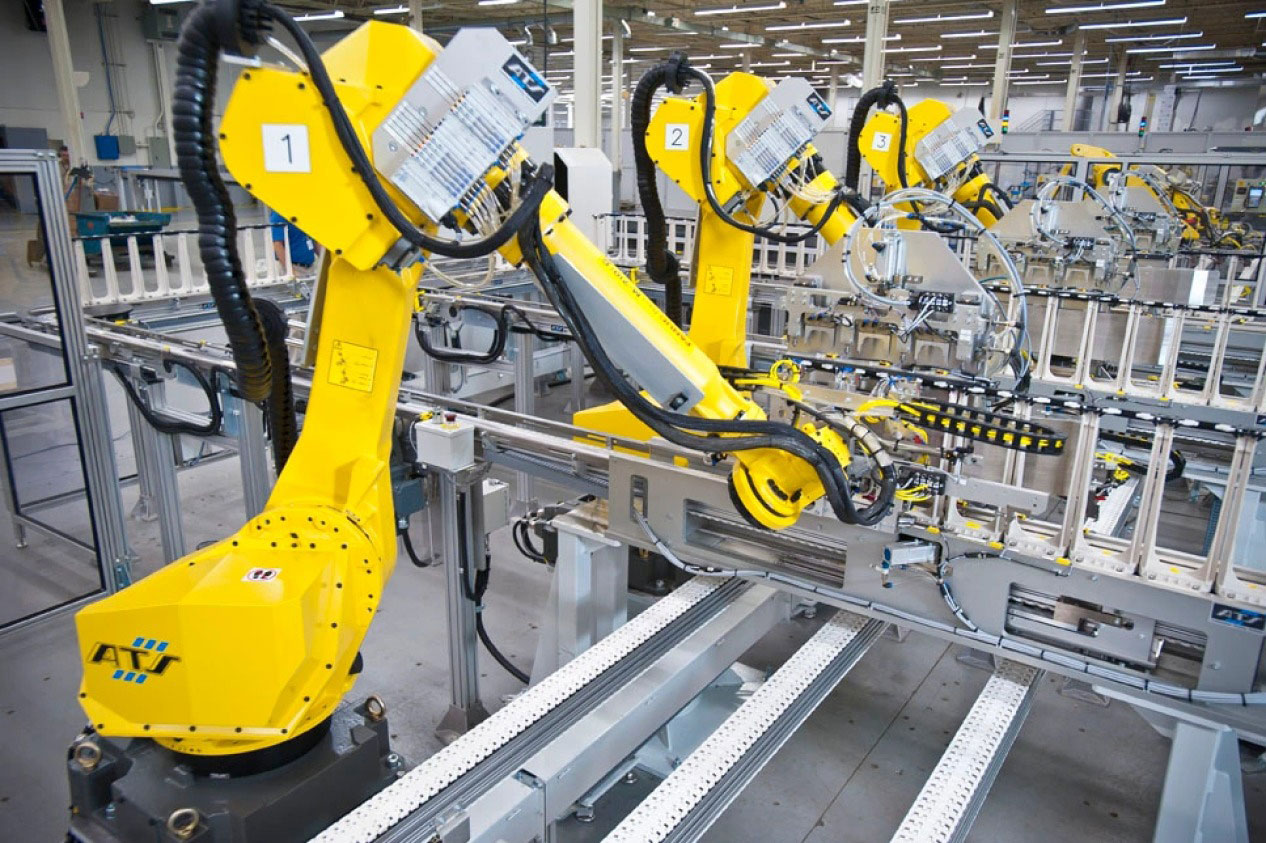

Process automation is made possible with the flexible gripping and handling of parts by robots. We specialize in customized turnkey robotic systems that can handle a variety of processes for both sterile and non-sterile products.

Robots and Robotic Systems

We engineer customized turnkey robotic solutions that take into account all parameters like reach, payload, production environment and more.

- Systems that provide a higher rate of flexibility and precision than ´normal´ systems

- SCARA & Delta Motion Planning; Smart Velocity & Acceleration Profiles; Third-Party Product Integration

Robot Applications

TRAYHANDLING ROBOTICS

We specialize in customized turnkey robotic systems that can handle a variety of trayhandling processes for both sterile and non-sterile manufacturing applications.

PALLETIZING ROBOTICS

We specialize in customized turnkey robotic systems that can handle a variety of palletizing processes for both aseptic and non-aseptic applications.

BIN PICKING ROBOTICS

Process automation is made possible with the flexible gripping and precision handling of parts by robots.

Key Benefits

Build the factory of the future now with standardized or customized solutions.

In-house Process & Motion Planning

In-house Process & Motion Planning

Identify constraints and optimize movements to achieve speed, precision and repeatability in manufacturing processes.

In-house Design & Build

In-house Design & Build

We engineer customized turnkey robotic solutions that take into account all parameters like reach, payload, production environment, and more.

Cycle Time Analysis & Optimization

Cycle Time Analysis & Optimization

Identify and improve any points of friction impacting efficiency and output to optimize parameters like reach, payload, production environment and more.

Third-Party Product Integration

Third-Party Product Integration

We partner with leading providers of specialty robots used in manufacturing and integrate them into your application.

Resources

BLOG

Robotic Trayhandling and Palletizing – Integration or Automation

This technology can be scaled for applications from highly specialized aseptic pharmaceutical applications to dark factories.

Customized Industrial Robotic Solutions

We are your one-stop partner for turnkey robotic systems for Assembly, Part Handling, Primary Packaging, Secondary Packaging, Vision Guided Manufacturing, and more

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube